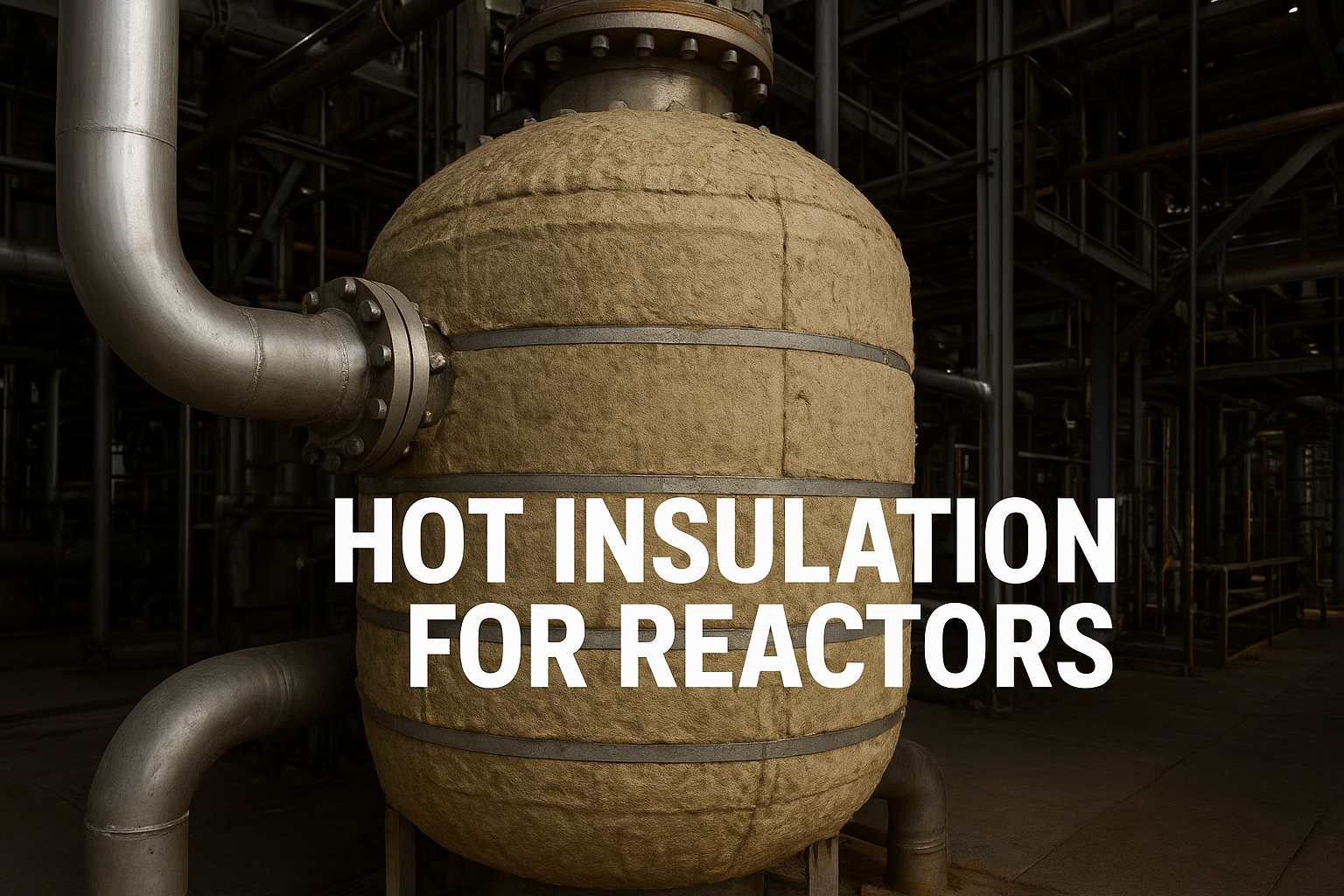

In industries like chemicals, pharmaceuticals, petrochemicals, and food processing, reactors play a crucial role in handling high-temperature processes. Maintaining the right temperature inside a reactor is essential for safety, efficiency, and product quality. This is where hot insulation becomes a vital part of plant operations.

Hot insulation for reactors is more than just wrapping a surface—it’s a technical process designed to reduce heat loss, protect equipment, and maintain stable process conditions. In this blog, we explore why reactor hot insulation is essential and how it benefits your industrial system.

What is Hot Insulation for Reactors?

Hot insulation involves applying heat-resistant materials such as Rockwool, Mineral Wool, Ceramic Wool, and LRB mattresses to reactor surfaces that operate at high temperatures. The goal is to:

- Control heat loss

- Maintain stable internal temperatures

- Improve safety and equipment lifespan

- Reduce operational energy consumption

Reactors often operate at temperatures ranging from 150°C to 800°C, depending on the industrial process. Proper insulation ensures they function efficiently without unnecessary energy waste.

Why Reactor Hot Insulation is Important

1. Reduces Heat Loss

Reactors consume significant energy to maintain process temperatures. Without insulation, heat escapes through the surface, increasing fuel or power consumption. Hot insulation greatly reduces this loss, leading to lower energy bills and improved process stability.

2. Ensures Safety & Operator Protection

Reactor surfaces can reach extremely high temperatures. Uninsulated surfaces pose serious safety risks to workers.

Hot insulation ensures the outer surface remains at safe touch levels, reducing chances of:

- Accidental burns

- Workplace injuries

- Safety violations

This creates a safer, compliant operating environment.

3. Protects Reactor Structure & Extends Lifespan

Constant heat exposure can cause metal fatigue, corrosion, and structural degradation. Insulation reduces extreme temperature fluctuations, helping reactors last longer with fewer maintenance issues.

4. Maintains Process Accuracy & Product Quality

Temperature stability is critical in reactors, especially in chemical and pharma production. Hot insulation helps maintain consistent thermal conditions, ensuring:

- Proper reaction rates

- Reliable batch quality

- Reduced production variations

5. Prevents Condensation & Moisture Damage

In some systems, temperature differences lead to condensation buildup. Insulation eliminates this risk by maintaining controlled surface temperatures.

Common Insulation Materials Used for Reactors

Depending on temperature range and process requirements, the following materials are commonly used:

- Rockwool & Mineral Wool Slabs

- LRB (Lightly Resin Bonded) Mattresses

- Ceramic Wool Blankets

- Calcium Silicate Boards

- GI / Aluminum Cladding Sheets

- SS Cladding for High-Corrosion Zones

These materials offer high thermal resistance, durability, and long-term stability.

Reactor Hot Insulation Installation Process

- Surface Cleaning & Preparation

- Material Selection Based on Operating Temperature

- Installation of Insulation Blankets / Mattresses

- Joint Sealing & Fixing with Wire/Clips

- Cladding Installation for Protection

- Final Inspection & Quality Check

A skilled team ensures that insulation is applied correctly for maximum efficiency and lifespan.

Benefits of Reactor Hot Insulation

- Up to 30–50% energy savings

- Safe working temperatures around reactors

- Improved process control & consistency

- Longer equipment life

- Reduced maintenance costs

- Better environmental performance

Hot insulation for reactors is an essential investment for any industry operating high-temperature processes. It ensures energy efficiency, safety, and long-term equipment protection—all while improving production quality.

If your plant operates reactors, regular inspection and proper insulation can significantly improve performance and reduce operational costs.

Need Professional Reactor Insulation Services?

Rabbitrun Technologies specializes in Hot Insulation for Reactors using high-quality materials and trained professionals. We ensure precise installation, long-lasting performance, and complete safety compliance.

📞 Contact us today for inspection or quotation!

rabbitruntechnologies@gmail.com | info@rabbitruntechnologies.com

+91-76230 12544

0 Comments